Liquid Cooling: Enhancing Efficiency in Servers and Beyond

Unveiling the Superiority of Liquid Cooling Solutions

In the realm of high-performance computing such as AI and cloud computing, liquid cooling systems for servers and server racks stand out as a beacon of efficiency, eclipsing the capabilities of traditional air cooling methods. Utilizing a water/glycol mixture, these innovative systems adeptly manage the substantial heat generated by modern CPUs and GPUs. The result? Outstanding performance, significantly reduced energy consumption and lower operational costs. Liquid cooling doesn’t just cool; it revolutionizes, allowing for increased density and enhanced performance in data centers. This marks a pivotal shift towards more sustainable, efficient computing environments, a change that aligns with global efforts to reduce energy usage and carbon footprints.

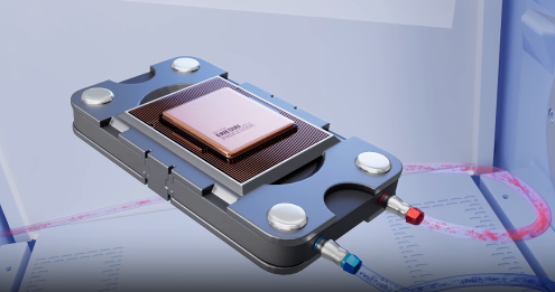

Bridging Technologies: From Electric Vehicles to Data Centers | Thermal Management and Pressure Testing Cold Plates

The application of liquid cooling is finding its way into data centers, finding synergy with the thermal management systems of electric vehicles (EVs) for example. In this automotive context, electronic control units (ECUs) leverage cold plates, circulating a heated or cooled water/glycol solution to maintain optimal temperatures. This similarity is not coincidental but rather indicative of the versatile utility of liquid cooling technologies. When applied to servers, cold plates offer an efficient means to dissipate heat, thereby ensuring the continuous, reliable operation of data centers. This cross-industry application underscores the adaptability and effectiveness of liquid cooling in various high-demand scenarios.

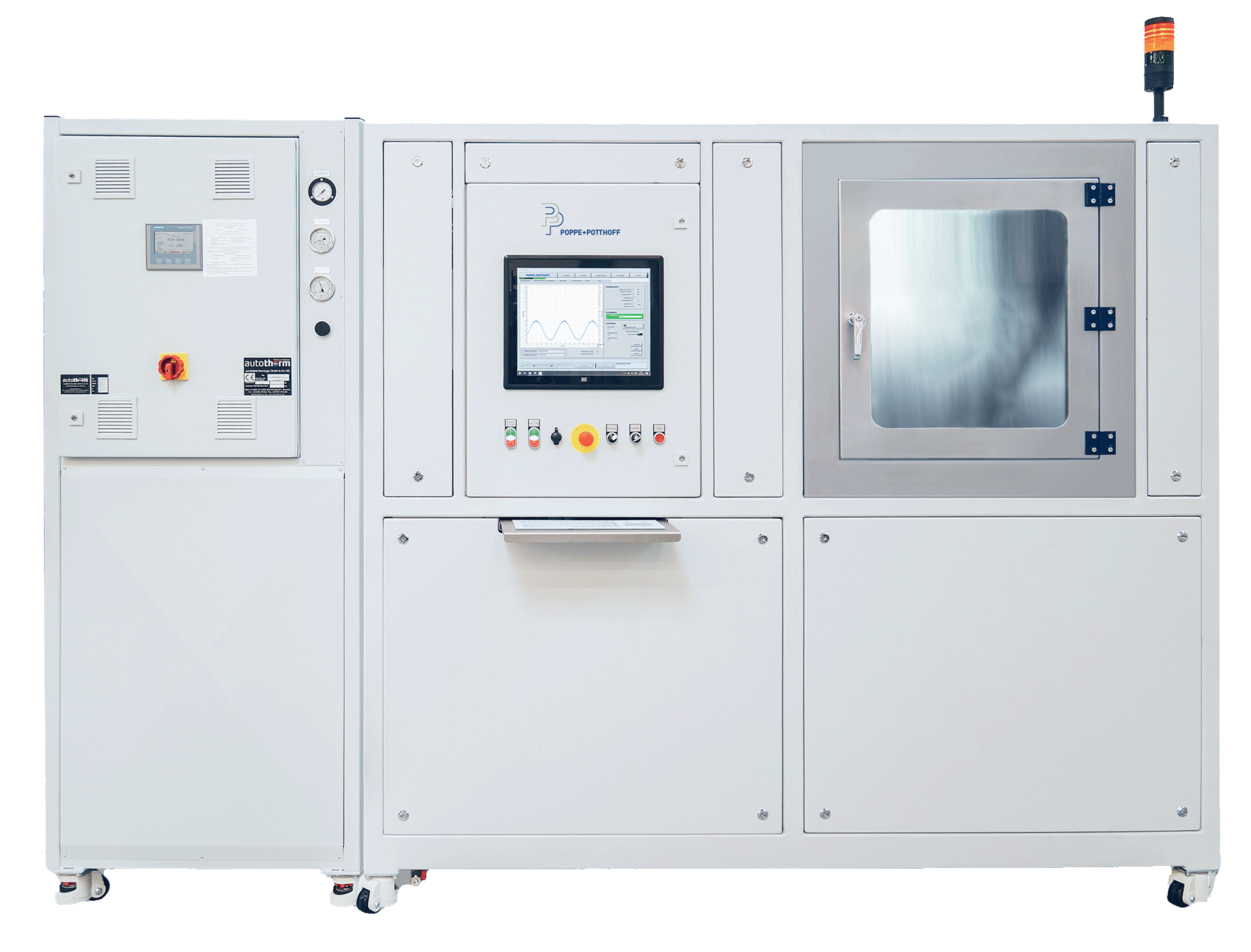

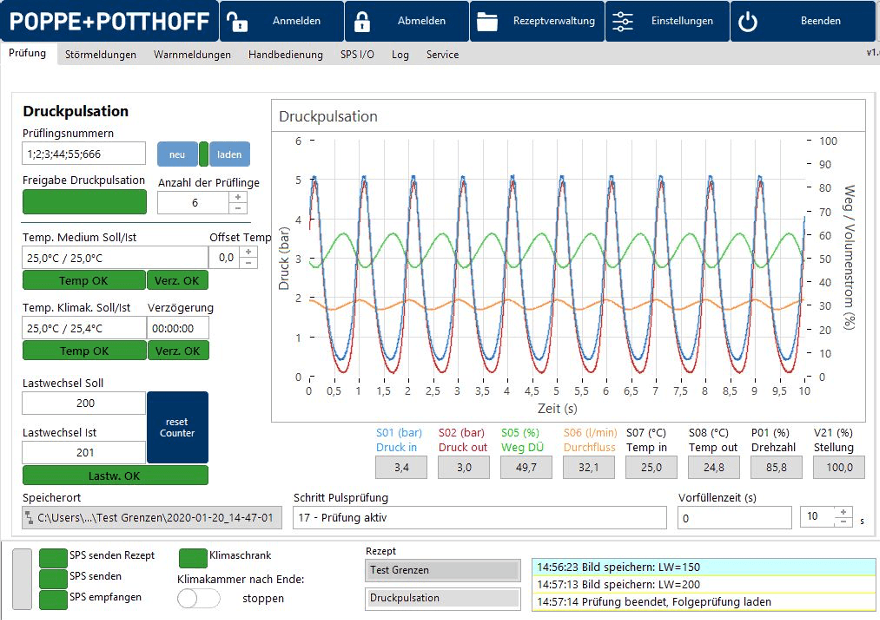

Emphasizing Rigorous Pressure Testing for Ultimate Reliability

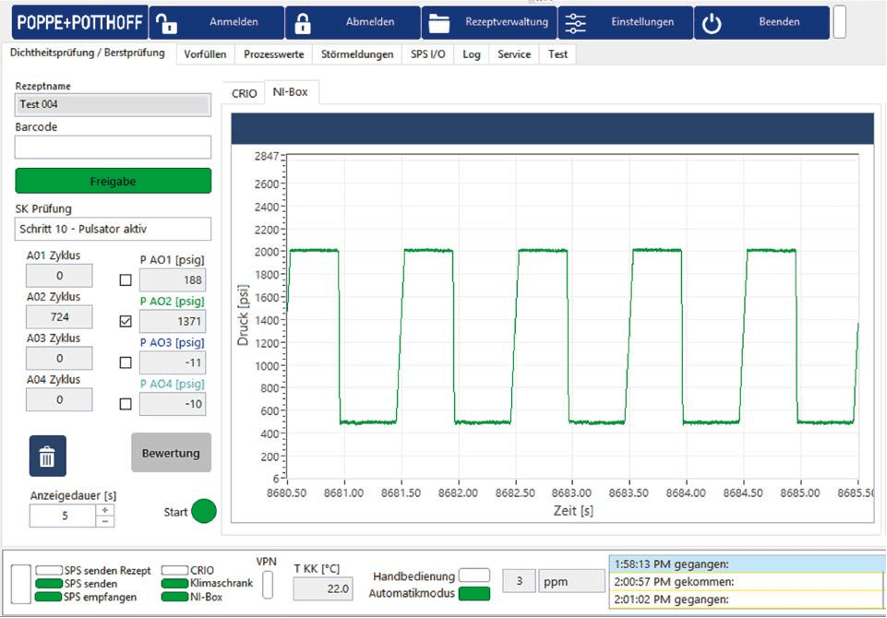

To guarantee the durability and performance of cooling components in both the automotive and IT sectors, comprehensive testing is imperative. Poppe + Potthoff Maschinenbau stands at the forefront of this essential process, supplying bespoke test systems that subject cold plates to wave (or square) pressure pulsations, varying temperatures of chilled water/glycol, and real-life condition simulations. Our state-of-the-art pressure test equipment is meticulously designed to validate the resilience of cooling plates for servers and server farms globally. Automotive tests often extend to include ambient temperature variations, reflecting external environmental challenges, whereas server components are scrutinized under more controlled conditions to hone in on internal efficiency. Through our rigorous testing protocols, we ensure that cold plates meet the exacting demands of high-performance computing and automotive applications, affirming their reliability and extending their service life.

This exploration into the world of liquid cooling systems sheds light on their critical role in advancing the efficiency and sustainability of today’s high-tech environments. With Poppe + Potthoff Maschinenbau’s innovative testing solutions, stakeholders can confidently deploy liquid cooling technologies, knowing they are built on a foundation of proven reliability and performance.

Summary: Fatigue and Burst Testing Cold Plates

Poppe + Potthoff Maschinenbau specializes in burst and pressure pulsation testing for coolant distribution racks and CPU and GPU cold plates, ensuring mechanical strength and tightness under cooling circuit pressure fluctuations. Our tests, critical for CPUs and GPUs, include burst pressures up to 35 bar (500 psi) and pressure cycle testing with PG25 up to 12 bar (175 psi), employing both wave and square curves at frequencies up to 2 Hz. Passive cold plates rely on external Coolant Distribution Units (CDUs) for circulation, eliminating the risk of failure from internal pumps.

Exemplary Test Norm

Hydrostatic Pressure Testing According to IEC 62368-1 G.15.2.1 for Liquid-Cooled Components

IEC 62368-1 Section G.15.2.1 outlines the requirements for hydrostatic pressure testing of pressurized, liquid-filled components. This part of the standard is particularly important for ensuring the safety and reliability of liquid cooling systems used in audio, video, information, and communication technology equipment.

The hydrostatic test is designed to verify that liquid-cooled components can withstand defined pressure loads without leaking or failing. For manufacturers and system integrators, compliance with this test is key to meeting global safety standards and ensuring long-term operational performance.

Other typical tests for cold plates of servers for example are burst- and leak tests, and the infrastructure is sometimes exposed to Water-Hammer tests.

Contact us to discuss your testing requirements!