Hydraulic booster units. Ready-to-connect units to increase the existing pressure for hydraulic applications.

Hydraulic

Compressed Air Boosters

Poppe + Potthoff Maschinenbau GmbH supplies compressor units, air amplifiers, nitrogen charging stations and pressure control systems of up to 400 bar for various gases. Thus, we offer ready-to-connect units to increase the existing pressure for pneumatic and hydraulic applications. In this way, the performance of existing systems can be increased flexibly and efficiently. Our compressor units are used wherever the existing system pressure is insufficient to implement specific applications. Air Amplifiers are suitable for the compression of pressurised air or nitrogen, while our boosters can be used for various kinds of testing and filling, recovery of gases or for other functions requiring high pressure.

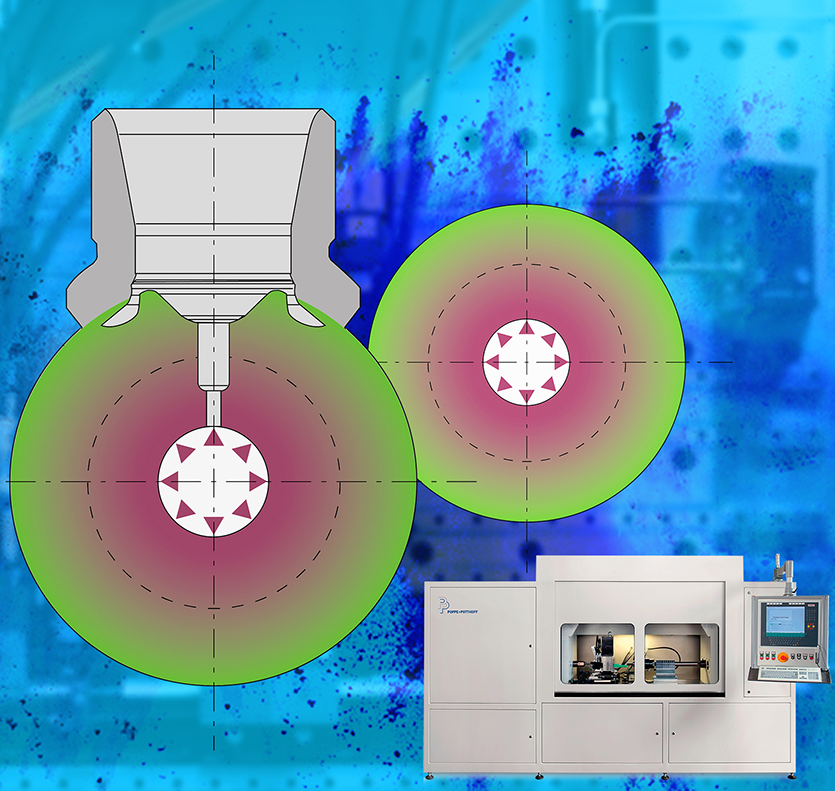

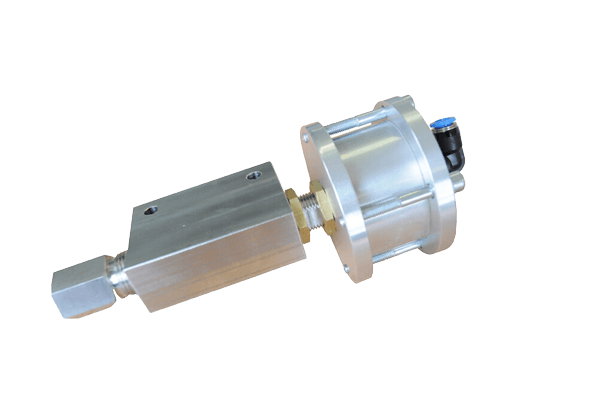

High-pressure valve

In addition to technical challenges in pressure generation, applications in high-pressure technology often require special high-pressure valves with the desired properties which are only very rarely available in the market. For this purpose, Poppe + Potthoff Maschinenbau GmbH develops and manufactures high-pressure valves for the control and regulation of volume flows in hydraulic applications. The valves are pneumatically or electrically controlled.

Performance Data

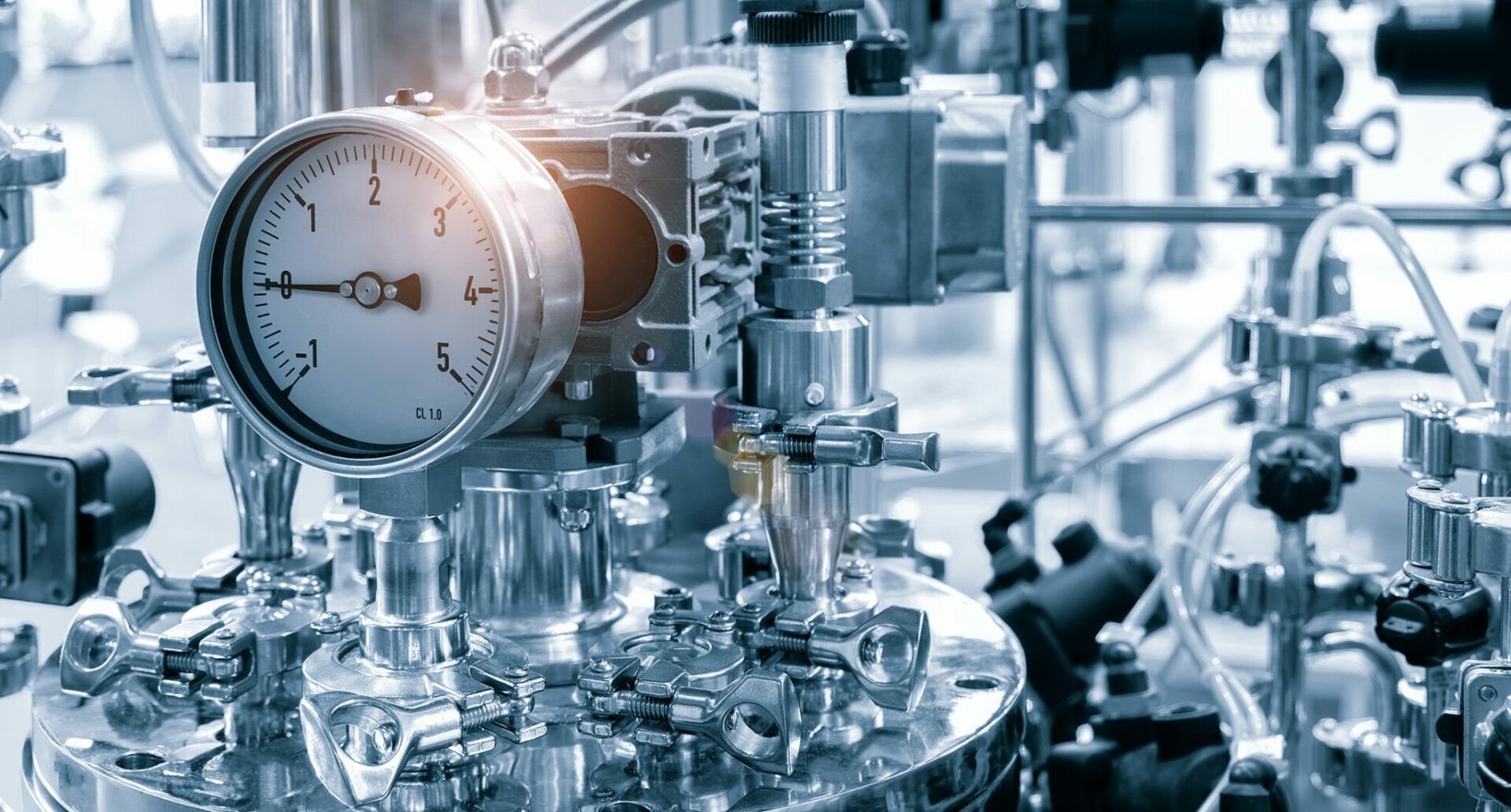

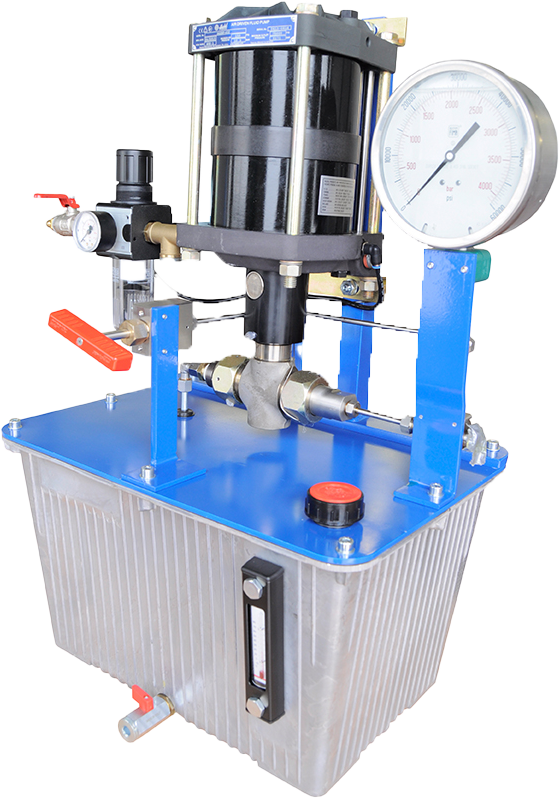

High-pressure hydraulic units for oils

Poppe + Potthoff Maschinenbau GmbH supplies ready-to-connect hydraulic units up to 4,000 bar. A pneumatically driven piston pump is used for pressure generation. The pump is simply connected to the existing domestic air supply network. Accordingly, no electrical connection is necessary for the construction of the pressure. Our hydraulic units are available in various pressure stages and are used, for example, in hydraulic clamping systems.

The desired operating pressure is set at the hydraulic units by means of a pressure reducer on the pneumatic drive side. The transmission ratio (e.g.: 1:600) provides the desired operating pressure. For example, a 5-bar inlet pressure corresponds to an operating pressure of 3,000 bar. When the desired high pressure is reached, the pump stops automatically and thus no longer consumes energy.

A shut-off valve allows the separation of the unit and pressure output. The expansion valve also allows the pressure to be released into the tank.

Performance Data (4000 bar unit)

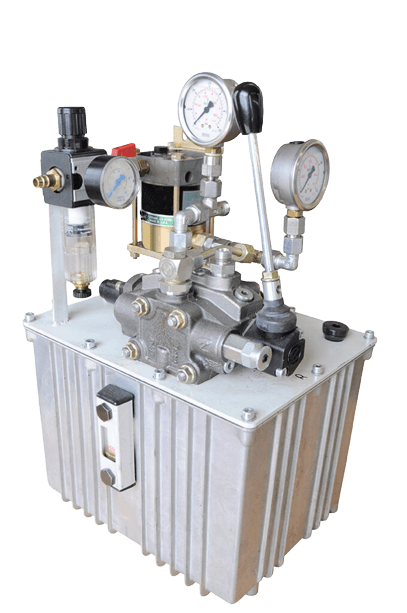

High-pressure hydraulic units for water

In addition to the classic oil hydraulic units, Poppe + Potthoff Maschinenbau GmbH also supplies ready-to-connect water hydraulic units of up to 4,000 bar. The design of the units is largely identical to the oil hydraulic units. Water hydraulic units serve, for example, as a drive medium for washing pumps in machine tools. These systems are also available at various pressure levels and require only compressed air from the domestic air supply network as the drive medium.

The desired operating pressure in the hydraulic units is set by means of a pressure reducer on the pneumatic drive side. The pressure ratio (e.g.: 1:600) produces the desired operating pressure. For example, a 5-bar inlet pressure corresponds to an operating pressure of 3,000 bar. When the desired high pressure is reached, the pump stops automatically and thus no longer consumes energy.

A shut-off valve allows the separation of the unit and pressure output. The expansion valve also allows the pressure to be released into the tank.

Leistungsdaten (4000 bar Aggregat)

Mobile pressure regulation systems

With the mobile pressure unit/pressure truck, a hydraulic pressure of up to 4,000 bar can be generated. Hydraulic supply and pressure translators are designed to customer requirements. The oil is filtered and passed via quick couplings to the proportional valve, which is mounted directly on the pressure translator and regulates the pressure build-up according to the defined specifications. The high-pressure section consists of three high-pressure valves with a pneumatic drive. Calibration connections are accommodated on the pressure transmitter. The high-pressure accumulator is equipped with a 2/2-way valve, accumulator, safety valve, manometer, storage relief valve and a pressure switch with a digital display.

The mobile pressure unit, therefore, is a compact and automatic operating system for pressure generation and control, taking into account customer-specific media and purity classes.

Performance Data

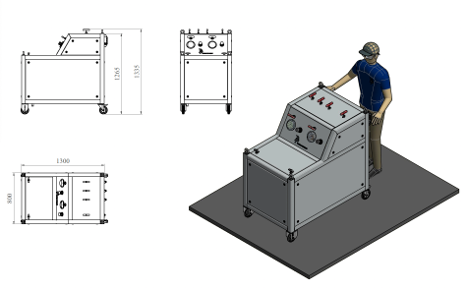

Hydraulic Pressure Booster Unit for High-Pressure Testing Applications

The Poppe + Potthoff hydraulic pressure booster unit is a robust and mobile solution for generating and regulating high pressures in oil and water circuits. Designed for use in production environments and test benches, this compact system features three independent pressure circuits and operates without additional energy consumption once target pressure is reached. Ideal for pressure testing, leakage testing, and component validation, the unit allows precise manual adjustment of pressure parameters. With stainless steel piping, integrated hose storage, and quick-connect fittings, it ensures safe and efficient operation.

Performance Data of the Pressure Booster

Test as a Service

We offer pressure tests in various pressure ranges as a test service. Whether for research and development or serial production, please contact us with your testing requirements.

PRESSURE TEST BENCHES AND APPLICATIONS

PRECISE, REPEATABLE AND RELIABLE

As a specialist in pressure testing technology and state-of-the-art test rigs, Poppe + Potthoff Maschinenbau supports the development and production of particularly resilient components made of various materials – especially for automotive, shipbuilding and mechanical engineering as well as fluid and the medical industry. We offer individually designed test benches such as burst pressure test rigs, pressure cycle test benches, leak test systems, functional test rigs and autofrettage systems.

Contact Us

Our experienced technical sales team will help you with the implementation of your project and will find a solution tailored to your specifications and your requirements. We are represented internationally and can support you and your company worldwide. Our team has completed hundreds of projects many of which involved supporting test facilities with identical equipment. P+P Maschinenbau is your internationally trusted partner.

Expertise, excellent knowledge of the market and affinity for our products guarantee our success.