Pressure Test Stands For

Automotive-Components

Automotive testing puts full vehicles, components and systems through a series of tests, both virtual and real-world simulations are conducted to ensure safety, reliability and compliance with safety regulations. Automotive testing is required to access global automotive markets and manufacturers must show they have put their product through rigorous assessment. Testing covers a wide range of vehicle features, and Poppe + Potthoff Maschinenbau supports the industry with state-of-the-art pressure test rigs, autofrettage systems and function test benches.

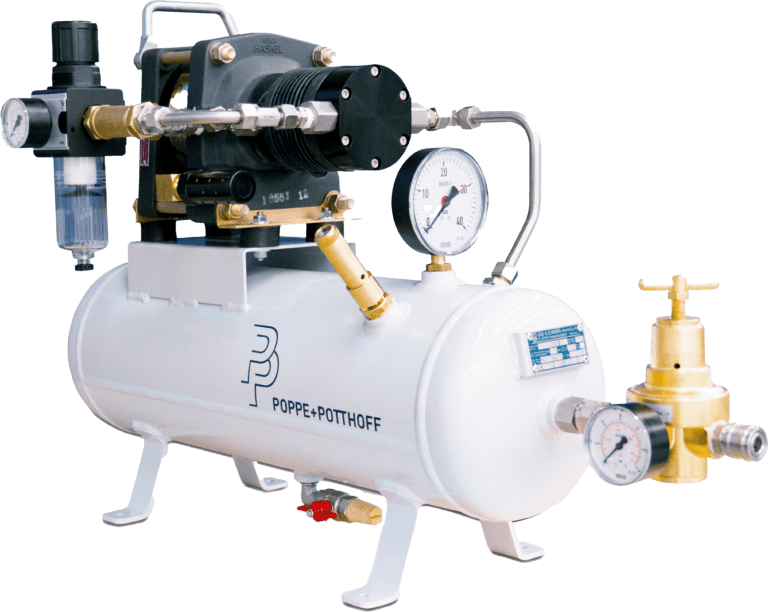

Liquid Cooling Burst- and Pressure Cycle Test Rig

Poppe + Potthoff Maschinenbau leads in burst and pressure pulsation testing for liquid cooling components like coolant distribution racks, manifolds, and CPU/GPU cold plates. Our rigorous testing ensures these components can withstand extreme pressure fluctuations, with burst pressures up to 70 bar (1100 psi) and pressure cycle testing at up to 20 bar (290 psi) using PG25 coolant. We utilize both wave and square pressure curves at frequencies up to 2 Hz, providing a comprehensive simulation of operational conditions. Additionally, our testing of passive cold plates, which rely on external Coolant Distribution Units (CDUs), further guarantees system reliability by mitigating internal pump failure risks.

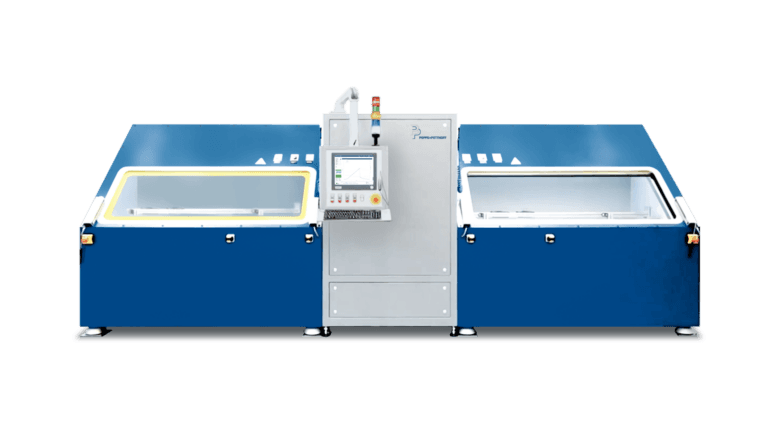

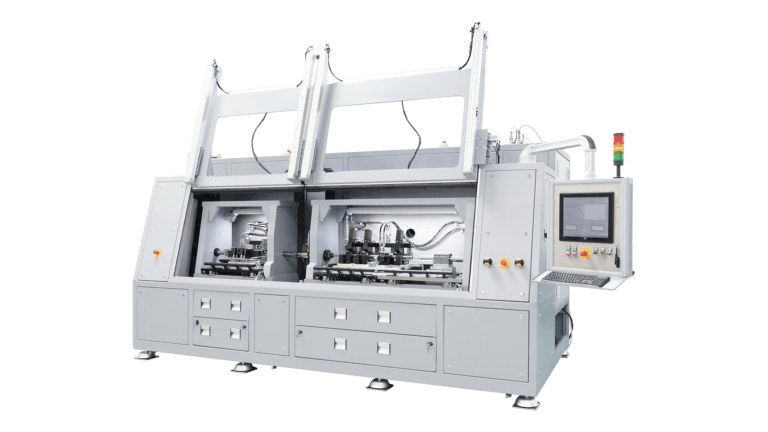

Large Components | Burst- and Pressure Cycle Test Rig

The test stand has two large chambers in which individual burst pressure and pressure cycle tests can be executed. Our state-of-the-art P+P flex pressure intensifier covers large components, such as accumulators, and generates pressure load changes of up to 800 bar with a frequency of up to 10 Hz.

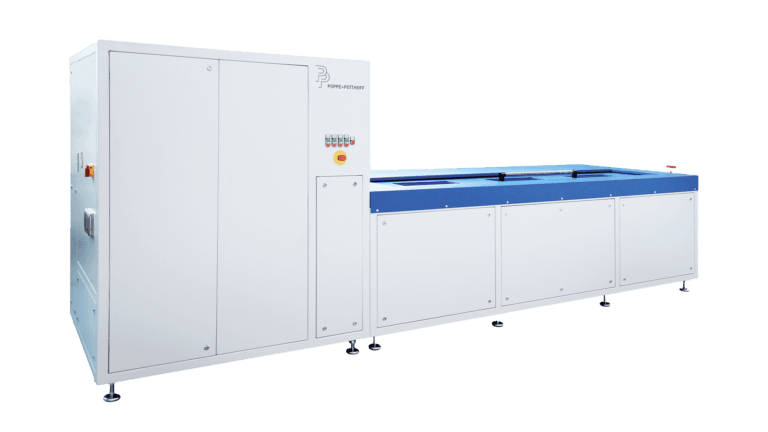

Hose Test Bench with Laser Measurement

When hoses are subjected to pressure, they often change from their original form and dimension. The test stand has an integrated automatic laser and length measurement system and can measure torsion easily. In addition, a quick connector system enables the hoses to be replaced rapidly.

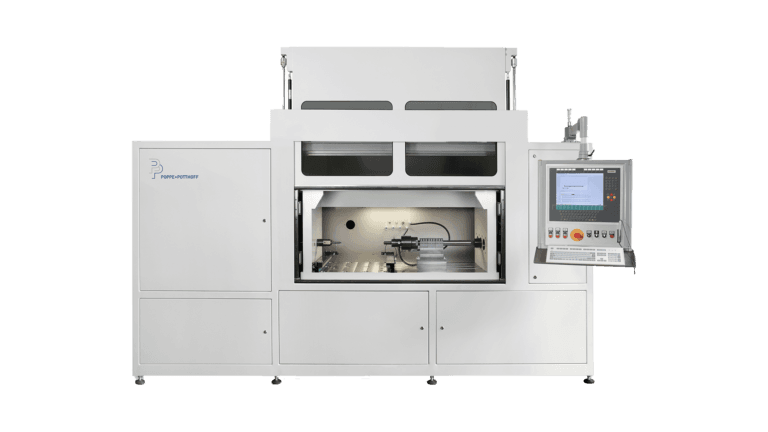

Autofrettage for R&D and Prototypes

The autofrettage system is ideal for research and development and prototype manufacturing. The rig enables manufacturers to mount different components with a flexible fixture system. Therefore a high variety of components, designs and prototypes can be autofretted on the system.

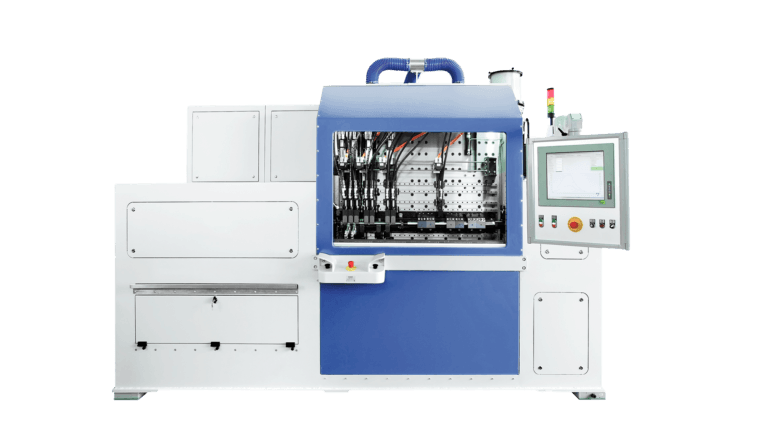

Common Rail Serial Production Autofrettage

This state-of-the-art autofrettage system is the perfect solution for the serial production of common rails. Our flagship system is utilized by manufacturers around to world. It enables improvement of the fatigue strength of common rails, injection lines and other components.

Future in Sight

Highlights

We are your partner for technical innovation. We are enthusiastic about new ideas, approaches and most of all technology. Therefore we contribute our expertise and turn the imaginable into the feasible. E-mobility components are subject to new test standards and must withstand various pressure tests. As an innovative and solution-oriented market leader, we support you with test benches for research and development as well as production. Our test benches are individually tailored to your requirements and can be equipped with a climate chamber for environmental simulation and media temperature control. Typical for e-mobility are tests with a water-glycol mixture of up to 12 bar while controlling a fluid flow and simulating both ambient and fluid temperatures between -40°C and 140°C.

News

about Automotive

How to Validate Oil and Hydraulic Filters with Pressure Cycle & Burst Testing

Oil and hydraulic filters are subjected to significant stress during operation. From repeated pressure pulses to sudden spikes in flow,…

China 6 Emission Standards: Why Pressure Testing & Autofrettage Are More Critical Than Ever

Introduction: The Global Shift Towards Stricter Emission Standards In recent years, the automotive industry has faced increasing pressure, not just…

See you at THE BATTERY SHOW NORTH AMERICA

7.-10. Oktober 2024 | Detroit MI | Huntington Place We are thrilled to invite you to THE BATTERY SHOW 2024 in…

Contact Us

Our experienced technical sales team will help you with the implementation of your project and will find a solution tailored to your specifications and your requirements. We are represented internationally and can support you and your company worldwide. Our team has completed hundreds of projects many of which involved supporting test facilities with identical equipment. P+P Maschinenbau is your internationally trusted partner.