Pressure Proof, Leak Testing, and Autofrettage of COPVs: Ensuring Safety and Structural Integrity

Composite Overwrapped Pressure Vessels (COPVs) are at the heart of modern hydrogen and space applications. From automotive fuel tanks to spacecraft storage, they combine lightweight composite materials with high-strength liners to withstand extreme pressures. But before these vessels can be safely used, they must undergo rigorous testing including a beneficial COPV autofrettage.

In this post, we’ll explore two key processes: pressure proof testing and autofrettage of COPVs, and why autofrettage is becoming a decisive step for long-term safety and performance. Poppe + Potthoff Maschninenbau has recently partnered with Maximator, bringing together two pressure testing experts and allowing us to leverage Maximator’s long-standing industry know-how to deliver state-of-the-art COPV proof pressure, pressure hold, and autofrettage systems.

Pressure Proof Testing – Verifying Strength Under Load

Proof testing is a hydrostatic test where the COPV is filled with water and pressurized to around 1.5 times its nominal working pressure. The purpose is to confirm the structural integrity of the vessel without causing permanent deformation.

- Detects weaknesses in materials and construction

- Validates compliance with international standards (EC79, UN R134, ISO, etc.)

- Ensures safety margins before deployment

Our modern test benches are equipped with automated tilting chambers, precision data acquisition, and remote monitoring, making proof pressure and pressure hold tests safe and repeatable.

Autofrettage – Extending the Life of COPVs

While proof and leak tests validate today’s safety, autofrettage prepares the vessel for tomorrow’s stresses.

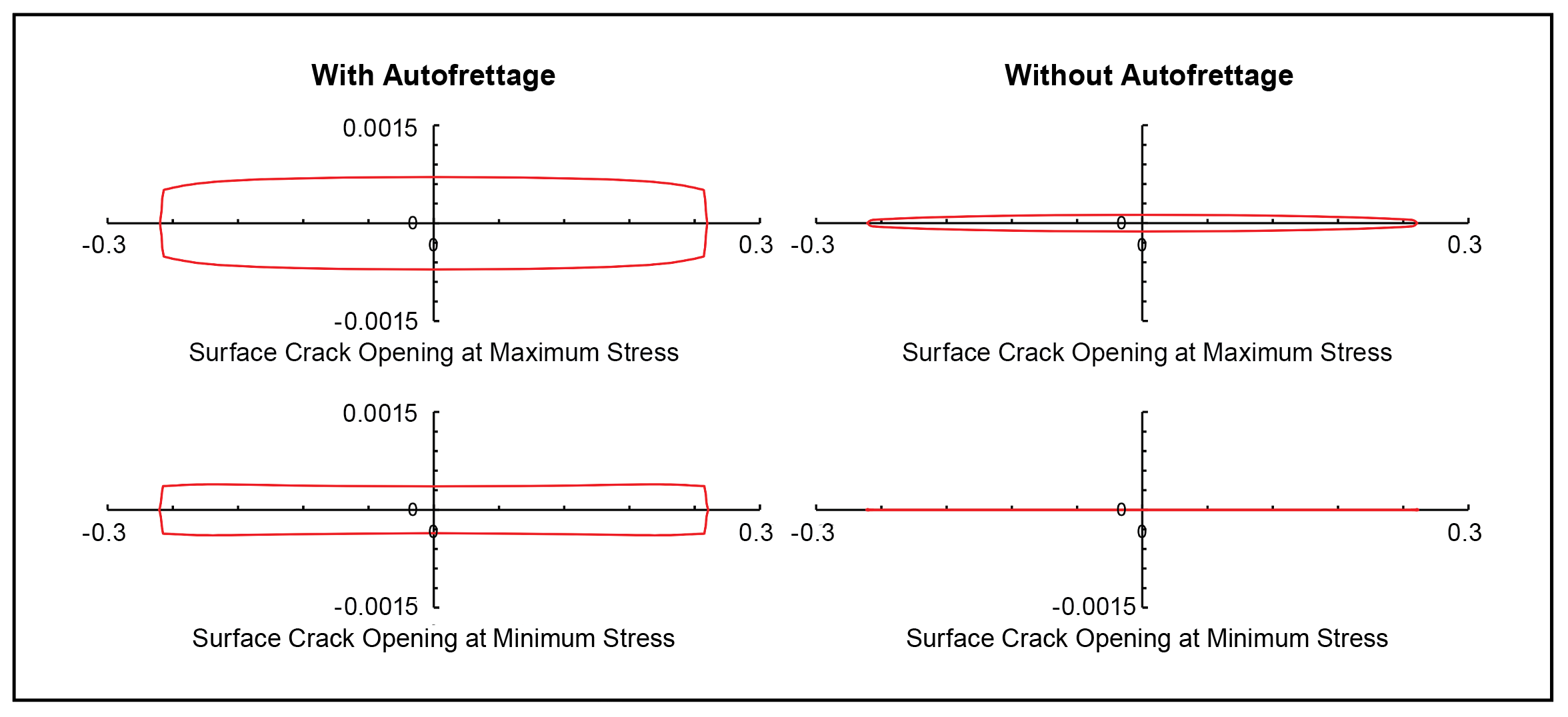

Autofrettage is a controlled over-pressurization of the vessel that plastically deforms the metallic liner while leaving the composite layers in an elastic state. This creates residual compressive stresses that significantly improve fatigue life and resistance to stress rupture.

Why Autofrettage Matters

- Increases resistance against crack initiation and propagation

- Reduces risk of stress rupture, a key life-limiting factor for COPVs

- Extends vessel lifetime in demanding cyclic pressure environments

- Aligns with NASA findings that better understanding of stress effects is crucial for long-term safety (NASA COPV research article)

NASA Findings on COPV Structural Life

NASA has conducted extensive research into the long-term safety and structural life of COPVs, especially in aerospace, where vessels face decades of cyclic loading. One of the key takeaways is that stress rupture and liner cracking are major life-limiting factors. To address this, NASA emphasizes:

- The need for better predictive models for composite and liner behavior over time

- Understanding how residual stresses affect fatigue and crack growth

- The importance of qualification processes that reduce long-term risks

This is where autofrettage becomes critical. By plastically deforming the metallic liner and creating beneficial residual compressive stresses, autofrettage directly mitigates the risks NASA identified. It helps ensure that cracks either do not initiate or, if they do, they remain stable and leak before burst.

Autofrettage therefore bridges the gap between proof of strength today and structural reliability over decades of service, aligning with the lessons learned from NASA’s research on COPV life extension .

Figure: NASA research on COPV structural life highlights the importance of understanding liner cracking and stress rupture. Image credit: NASA source.

Autofrettage is not just a test—it’s a life-extension process that makes COPVs safer, more reliable, and more cost-effective over their service life.

Conclusion

Pressure-proof tests validate strength. Leak tests ensure tightness. Autofrettage extends durability. Together, these processes form the backbone of safe COPV qualification and lifecycle management.

As hydrogen mobility and space applications rapidly grow, combining advanced test benches with processes such as autofrettage will be crucial to maintaining COPVs’ safety, reliability, and economic viability.

With this collaboration with Maximator, we bring together decades of expertise in designing, manufacturing, and commissioning pressure testing systems. For our customers, this means access to a solution built on proven engineering and real-world experience, and delivering maximum safety, reliability, and efficiency in daily operation. By combining strengths, we can offer not just a machine, but a long-term partnership that ensures your testing process is secure, traceable, and future-proof. – Johannes Montag, Managing Director at Poppe + Potthoff Maschinenbau GmbH

Upon request we can also offer Burst Testing Test Rigs of COPV after careful analysis and security assessment based on the volume of the COPV.