EV Market Outlook and Thermal Management

Electronic Vehicle Market

What the Future holds

In terms of market share, EVs still make up a relatively small percentage of the total vehicle market. However, this share is growing rapidly. In 2019, EVs represented about 2% of global car sales, up from less than 1% in 2015. According to the IEA, this share is expected to reach about 10% by 2025 and 30% by 2030.

It’s important to note that the growth of the EV market varies widely by region. In some countries, such as Norway and Iceland, EVs already make up a significant share of new car sales. In Norway for example, in 2019, EVs represented over 60% of new car sales. In other countries, such as the United States, the market share of EVs is still relatively small, but it is growing rapidly.

In addition, major automakers are investing heavily in the development and production of electric vehicles. Many have announced plans to phase out gasoline-powered vehicles and focus on electric and hybrid options. This shows a commitment to the growth of the EV market and is expected to contribute to the increase in market share in the coming years.

Thermal Management

Thermal management and testing are critical components in the design and development of electric vehicles. As EVs rely on batteries for power, it is crucial that these batteries are kept at optimal temperatures to ensure their longevity and performance.

Thermal management systems in EVs are designed to keep the batteries within a certain temperature range, typically between 20 and 30 degrees Celsius. These systems use a combination of heating and cooling elements, such as coolant, air conditioning and thermal insulation to regulate the temperature of the batteries. They also have sensors and control systems that monitor and adjust the temperature as needed.

Thermal management is especially important for fast charging, as the high currents and power levels used in fast charging can generate significant heat. If not properly managed, this heat can damage the batteries and reduce their overall performance and lifespan.

In addition to thermal management, testing is a critical component in the design and development of EVs. Testing is used to ensure that the batteries, thermal management systems, and other components of the EV can withstand the rigours of real-world use. This includes testing for things like thermal cycling, which simulates the temperature changes that the batteries will experience in different climates and conditions, as well as testing for vibration, shock, and impact to ensure the batteries can withstand rough roads and accidents.

Manufacturers also conduct extensive testing on the batteries themselves, including cycling tests, which simulate the charge and discharge cycles of the batteries over time, and capacity tests, which measure the total amount of energy the batteries can store.

In conclusion, thermal management and testing are essential for the development of electric vehicles. The thermal management systems help to keep the batteries at optimal temperatures and ensure their longevity and performance, while testing is used to ensure that the EV components can withstand the rigors of real-world use. This helps to ensure that EVs are reliable, safe, and efficient for consumers.

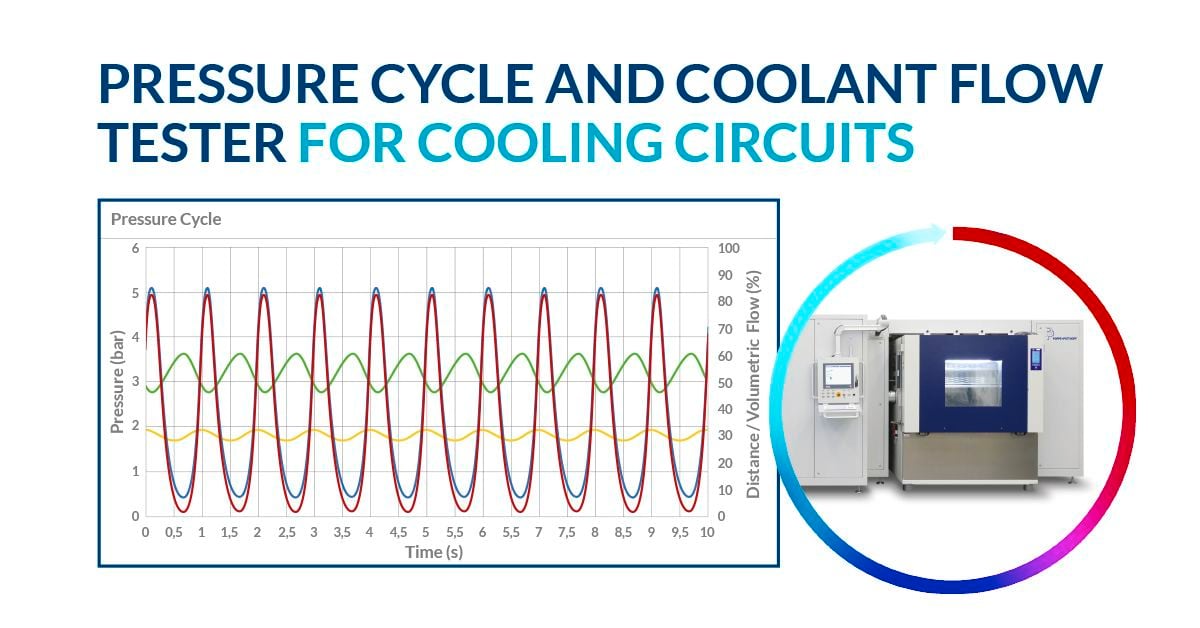

Pressure Testing Coolant Circuits

Pressure testing is an important step in the design and development of coolant circuits in electric vehicles. Coolant circuits are used to transfer heat away from the batteries and other critical components in the EV, and they need to be able to withstand high temperatures and pressures.

Pressure testing is used to ensure that the coolant circuits are free of leaks and that they can withstand the pressure and temperature changes that they will experience in real-world use. This includes both internal and external pressure testing. Internal pressure testing is used to ensure that the coolant circuits can withstand the pressures generated by the coolant flowing through them. External pressure testing is used to ensure that the coolant circuits can withstand the pressures generated by the outside environment, such as high winds or impacts.

Pressure testing is done using specialized equipment that can simulate the conditions the coolant circuits will experience in real-world use. This includes high-pressure pumps and test gauges that can measure the pressure inside the coolant circuits. The test also includes a visual inspection of the coolant circuit, looking for any signs of leaks or damage.

It’s important to note that pressure testing is not a one-time event, it’s a continuous process. This is because the coolant circuits are subject to wear and tear over time, so regular pressure testing is needed to ensure that they continue to function properly. At Poppe + Potthoff we offer test rigs that can run tests for months if required in order to understand the service life of a DUT.

In conclusion, pressure testing is an essential step in the design and development of coolant circuits in electric vehicles. It helps to ensure that the coolant circuits are free of leaks, can withstand high temperatures and pressures, and can continue to function properly over time. This helps to ensure that EVs are reliable, safe, and efficient for consumers.

Contact us today to learn how Poppe + Potthoff Maschinenbau can support your EV component testing project. We offer pressure cycle test rigs including heating and cooling the test media, as well as simulating ambient temperatures through climate chambers.