Leak test benches with water, molder gas, glycol, SF6, oil and gas up to 3000 bar. In order to ensure that components are manufactured without leaks, they are exposed to proof and pressure drop tests to identify leaks and weak spots.

Leak Test Stands

With Fluids and gas

Ensure Leak-Free Production with Poppe + Potthoff’s Advanced Leak Test Rigs

To guarantee that cast parts, on-tank valves, tubes, hoses, assemblies, and various other pressure vessels are manufactured without leaks, they undergo non-destructive (hydrostatic) leak testing. Common test media include oils, water, glycol, air, molder gas (with 5% hydrogen), nitrogen, and sulfur hexafluoride (SF6).

Understanding Leak Testing

A leak typically manifests as an unintended hole or crack in a component, leading to a pressure drop from high to low. When a pressure vessel or internal component exceeds normal atmospheric pressure, it is in a state of positive pressure. If a seal or crack connects the sealed high-pressure area with a lower pressure region, the positive pressure will escape to the lower pressure area, identifying the leak location.

Features of Our Leak Test Rigs

Custom Solutions for Leak Testing

Poppe + Potthoff Maschinenbau offers tailored leak testing solutions to ensure your pressure components are leak-free and reliable. Our advanced test rigs are designed to provide precise, repeatable results, enhancing the quality and safety of your products.

Trust Poppe + Potthoff Maschinenbau for high-quality leak test rigs designed to meet your specific testing needs and ensure the integrity of your pressure components.

Discover More Leak Test Stands

Detect leaks using underwater methods, pressure hold, drop tests, or vacuum testing. Compatible with various media and available with optional temperature conditions. Discover our leak testing options below!

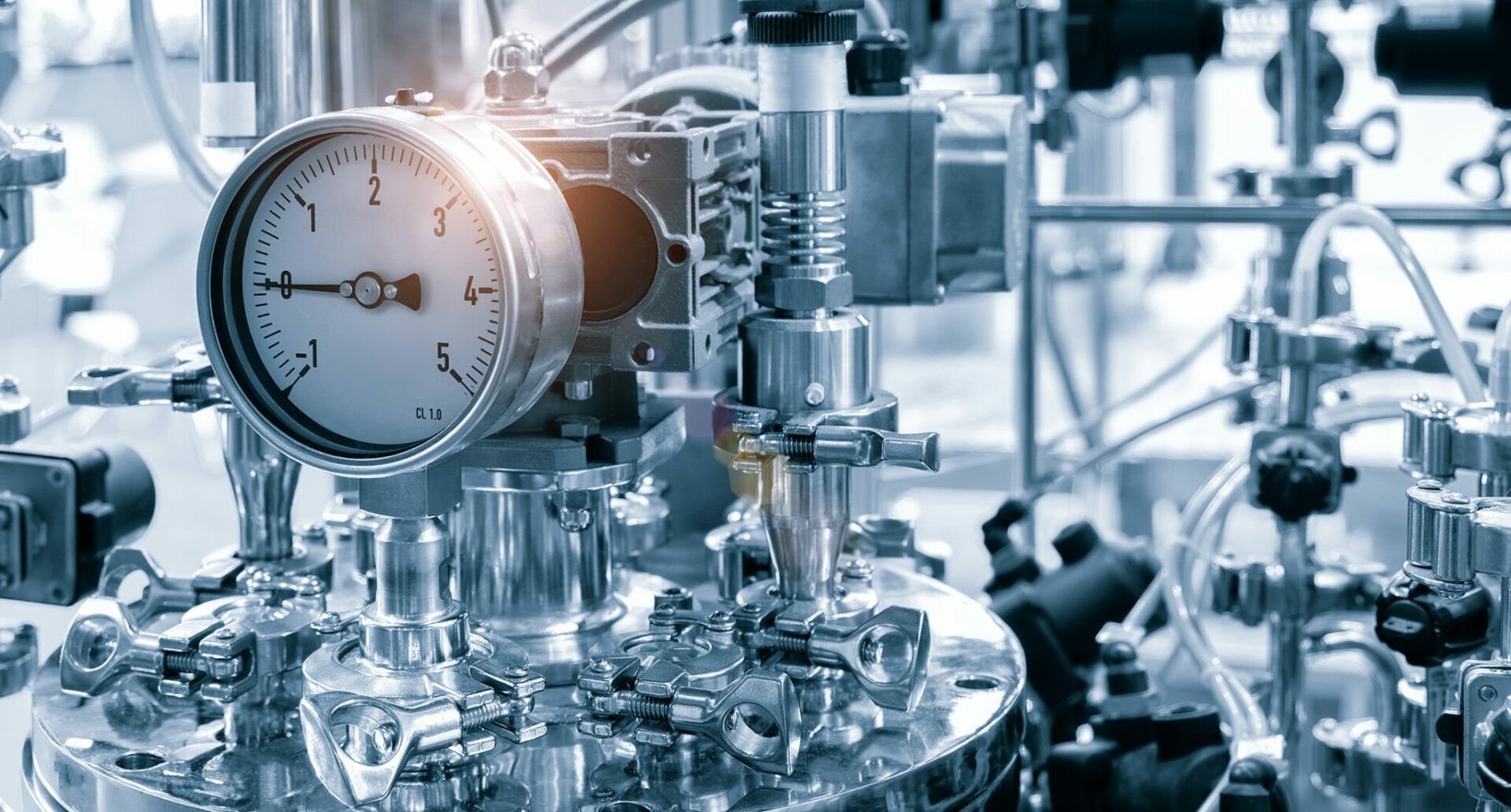

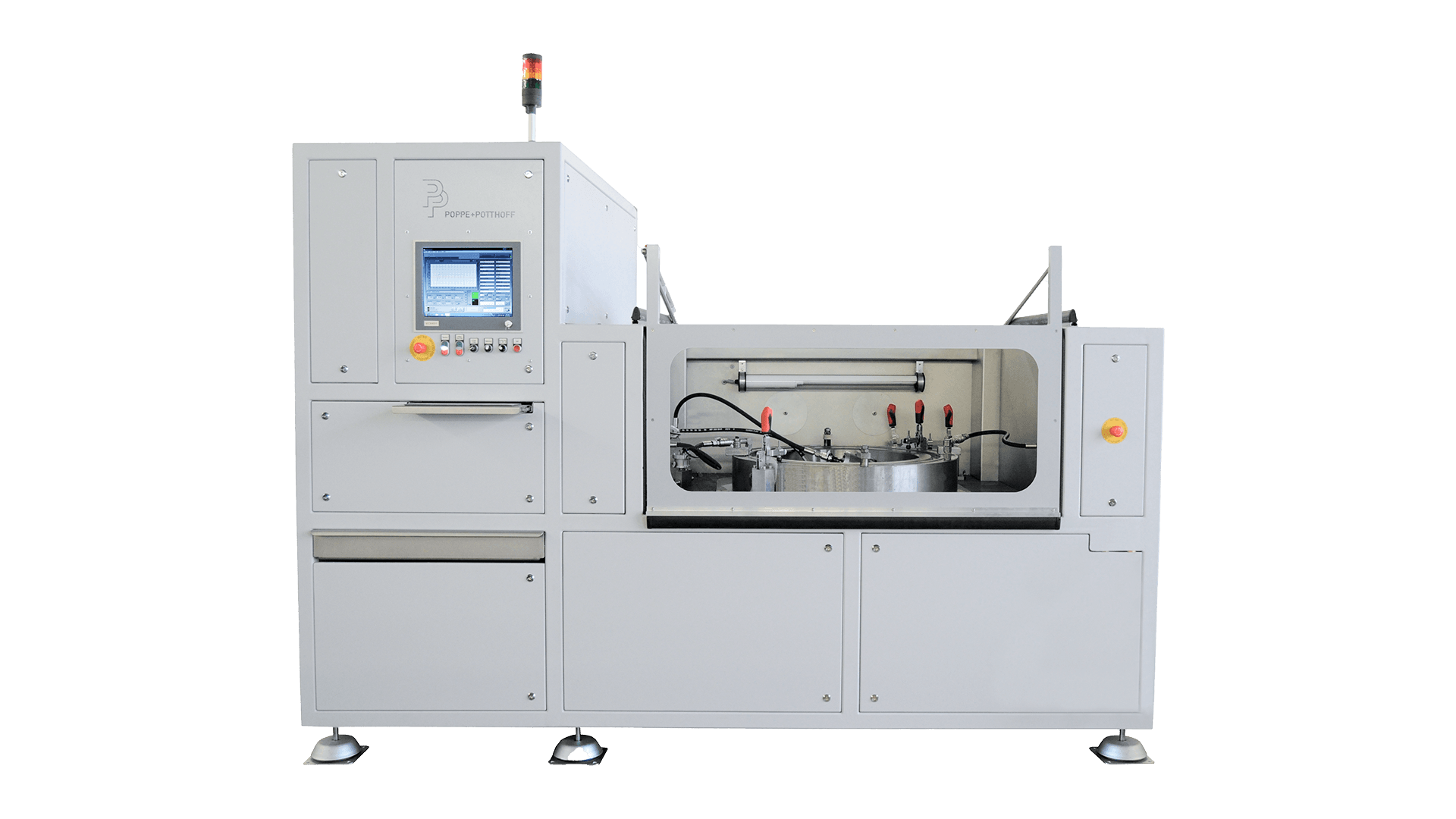

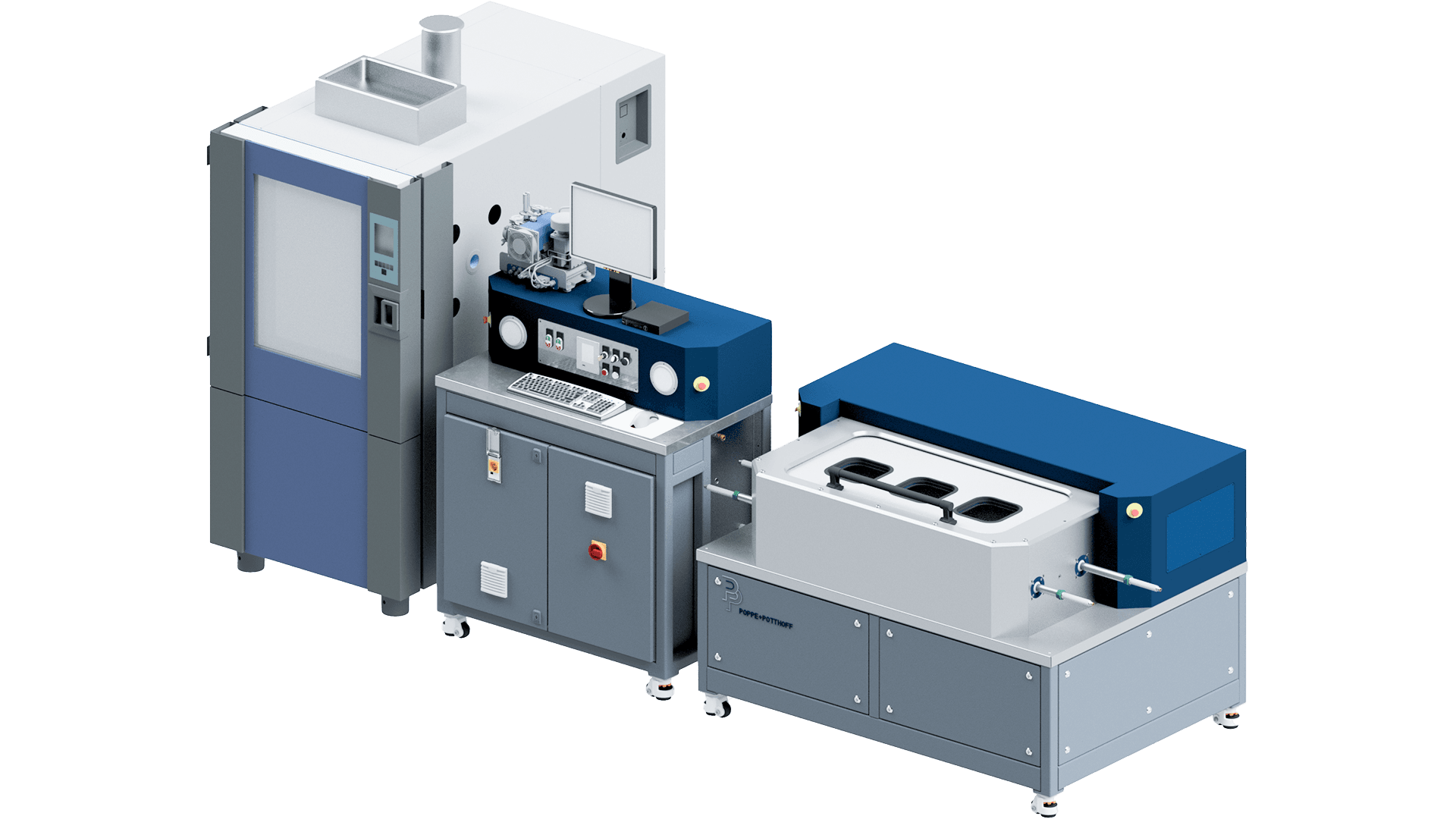

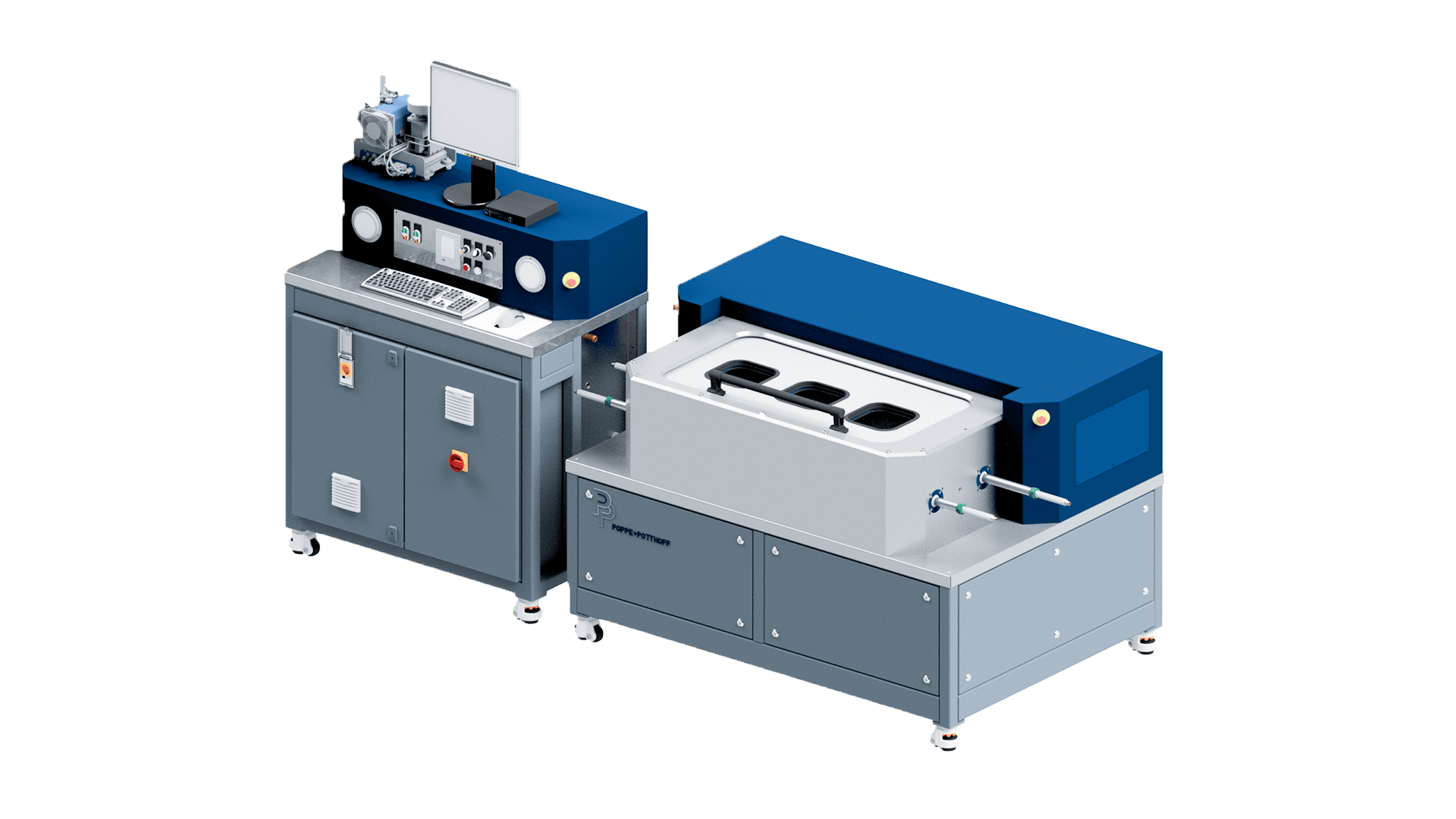

Multi-Purpose Leak Test Rig up to 3000 bar

Depending on the requirements the rig will be equipped with a pressure pump, our patented fine-control method, and a pneumatic or a hydraulic pressure intensifier to generate pressure. A PC allows programable pressure curves and test setups and extensive data acquisition, and visualization for optimal analysis. The rig allows various test setups tailored to customers’ test specifications.

Performance Data

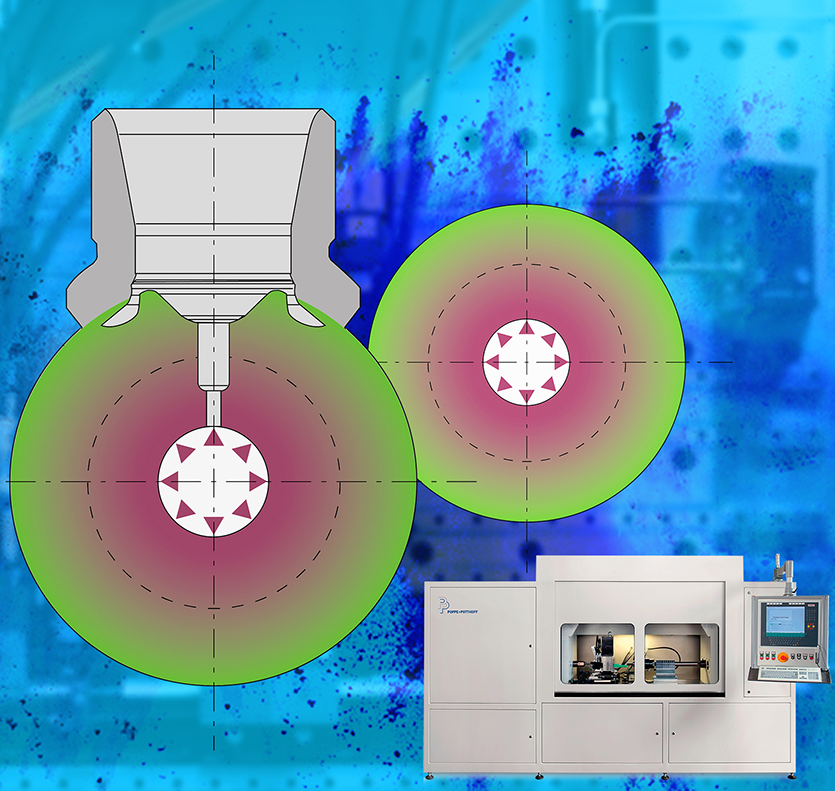

SF6 Leak Test Stand

The SF6 leak test rig allows tightness tests on common rails and other components. The pressure is generated through a pressure convertor, while the SF6 is contained in the high-pressure medium. A leakage is determined in the vacuum chamber with a laser sensor. For efficiency, a clamping device is located in the test chamber. It is adjustable and can be used for almost every type of common rail. Adaptation of the rails is enabled through high-pressure hoses and couplings. The control unit is a Siemens PLC and involves a touch panel as an input and display unit.

Performance Data

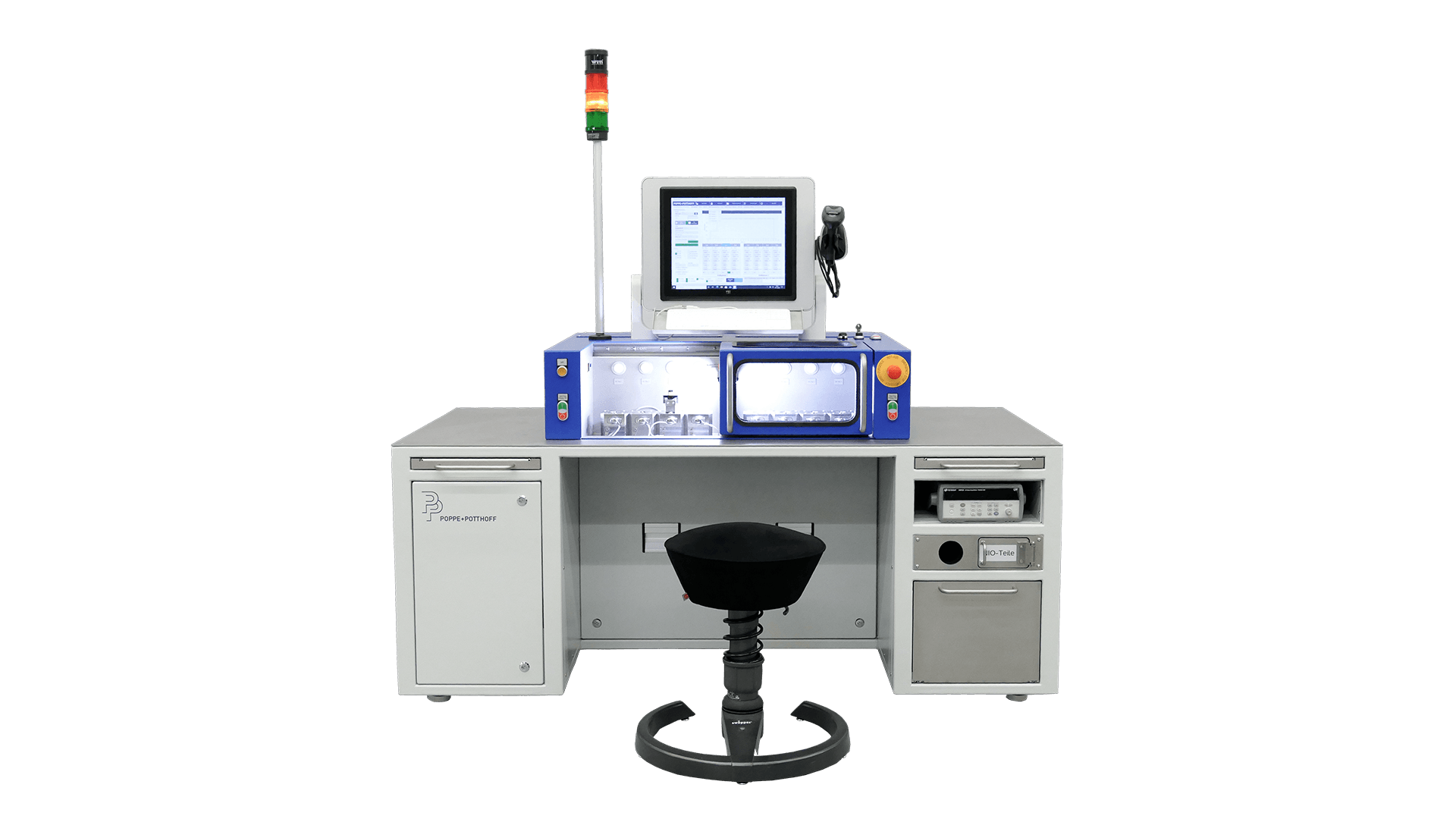

Leak test rig for Fittings

With the Poppe + Potthoff leak test systems valves, cast parts and many other (automotive) components and assemblies can be tested for leakage. The system allows pressure (drop) tests on a wide range of components up to a pmax. pressure of 1 000 bar. The pressure points are approached with a pressure intensifier and allow flexible pressure ramps and pre-programmed holding times. This unique system allows impulse pressure to be applied to the test DUT and allows trapezoidal (square) as well as sinusoidal (wave) curves.

Performance Data

Overpressure-vacuum test stand

The pressure leak test stand allows testing in various pressure ranges and is unique with its functionality of underpressure functionality. The leak test rig can achieve overpressure-overpressure, overpressure-vacuum, and vacuum-vacuum pressure ranges. The pressure is variably adjustable and can take place under a wide range of climatic conditions. Test temperatures of -72 ° C to + 180 ° C and a controllable humidity of up to 98% can be reached in a climate chamber. Three (or more) test connections are located on each side of the test chamber and can be shut off individually via separate valves. A leak test is detected at every DUT and excludes it from leakage from the test circuit.

Performance Data

Leak test bench <1050 bar with gas (helium)

The leak test stand is suitable for gas pressure tests up to 1050 bar. Tests can be performed with 95/5 moulder gas/H2, helium or nitrogen. Standard 50L gas cylinders or other sources serve as the media source. A leak is detected and registered by a sniffer (e.g. Inficon P3000XL).

The leak test stand is equipped with a special safety concept to protect the operator. New and never before components and prototypes are tested with water in a safety chamber for their bursting pressure (e.g. up to 3000 bar) to understand the component’s behaviour.

A safety box is installed in the climate chamber for testing with gas, which protects against potential component splinters. In addition, various flexible hoses are attached to the box and are equipped with nozzles to detect leakage at several points around the component. Consequentially, the hoses are connected to outlets outside the climate chamber. At the outlets, the operator can use the sniffer to identify the leak. For an underwater test, the safety box is removed or the door of the box is hung out. Frequently tested components in this system are H2 Ontank Valves.

Performance Data

Test as a Service

We offer several pressure tests in various pressure ranges as a test service. Whether for research and development or serial production, please contact us with your testing requirements for a non-binding offer.

PRESSURE TEST BENCHES AND APPLICATIONS

PRECISE, REPEATABLE AND RELIABLE

As a specialist in pressure testing technology and state-of-the-art test rigs, Poppe + Potthoff Maschinenbau supports the development and production of particularly resilient components made of various materials – especially for automotive, shipbuilding and mechanical engineering as well as fluid and the medical industry. We offer individually designed test benches such as burst pressure test rigs, pressure cycle test benches, leak test systems, functional test rigs and autofrettage systems.

Contact Us

Our experienced technical sales team will help you with the implementation of your project and will find a solution tailored to your specifications and your requirements. We are represented internationally and can support you and your company worldwide. Our team has completed hundreds of projects many of which involved supporting test facilities with identical equipment. P+P Maschinenbau is your internationally trusted partner.

Expertise, excellent knowledge of the market and affinity for our products guarantee our success.