Hydrogen: Pressure Testing

Hydrogen (H2) component test systems for research & development

Quality Control

Pressure Test Stands for Hydrogen Components

Quality inspection: In a vehicle, media-carrying components must withstand extreme strains at temperatures ranging from -40° C to +140° C. Poppe + Potthoff Maschinenbau develops testing systems to check and optimize them efficiently.

Hydrogen Components

Put to the (Pressure-) Test

Poppe + Potthoff Maschinenbau GmbH develops test systems for research & development and validation of media-carrying hydrogen components.

At Poppe + Potthoff Maschinenbau we offer test stands in the field of pressure pulsation testing, pressure cycle testing, burst pressure testing and hydrostatic (fatigue) testing. The test benches are used in various component testing setups. Some examples are: shut-off valves, connection parts for containers, flexible fuel lines, non-return valves, pressure regulators, pressure reducers, pressure relief valves, flow sensors and sensors for detecting hydrogen leaks.

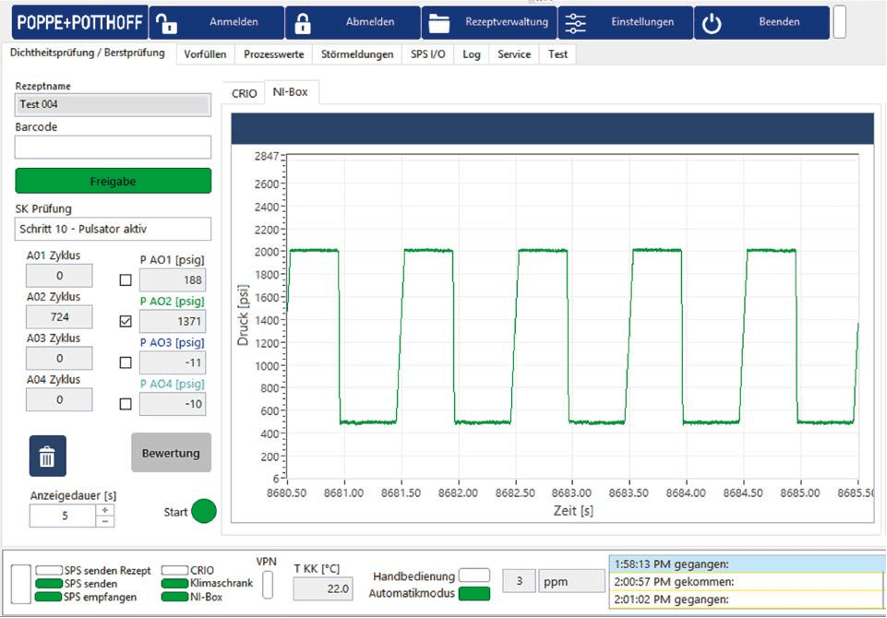

Hydrostatic pressure fatigue and burst test

In a typical test, the component is inserted into the test chamber of the burst test bench. This can be an auxiliary heater for a hydrogen car or valves, hoses and other hollow bodies that need to withstand more than 100,000 load changes over the lifetime of the vehicle (up to 15 years). The test benches of Poppe + Potthoff Maschinenbau allow for testing of the hydrostatic strength of components with pressures up to 3,000 bar or more.

Highlights:

Traction battery: It not only drives the engine but also supplies the vehicle‘s entire electrical system with power. In Poppe + Potthoff Maschinenbau‘s function test stand, the energy efficiency of heating and cooling units can be tested and optimised to increase the accumulator‘s performance.

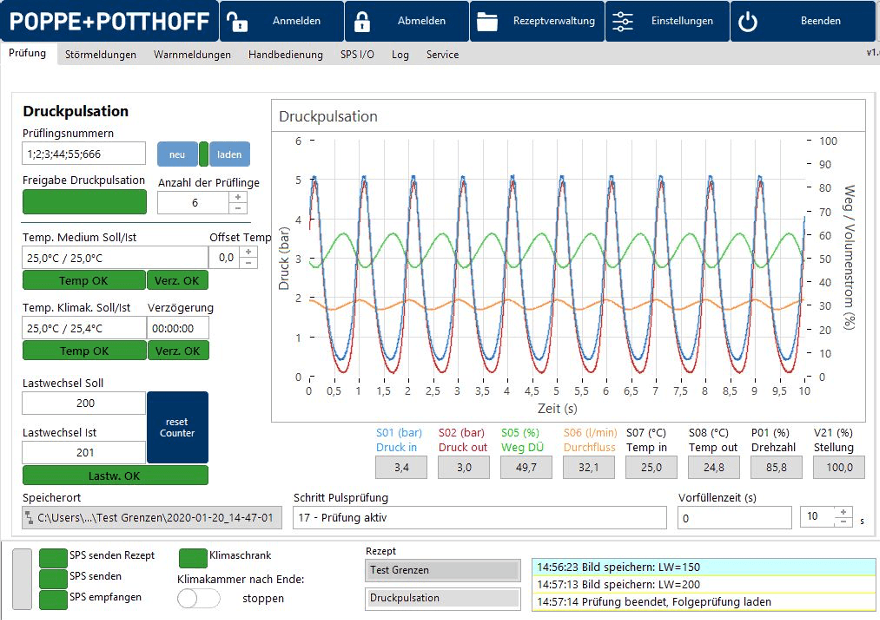

The flow rate of the test medium can vary from 1-50 l/min at a pressure of 0.2-12 bar or higher. The load changes are freely programmable with a sinusoidal or trapezoidal rise at a test frequency of 0.2-2 Hz or faster. The test stand can be used for complete systems, assemblies and components made of various plastics, metals and sealants. Weak points in the material combination – for example around a weld seam – can be sounded out and optimized early in the development process as well as during production.

Time-lapse for long-term tests

A long-term test usually takes 20-30 days, depending on the frequency of the load changes. The temperature and volume flow of the test medium as well as the ambient temperature (if the test takes place in the climatic chamber) vary according to the test specification.

Highlights:

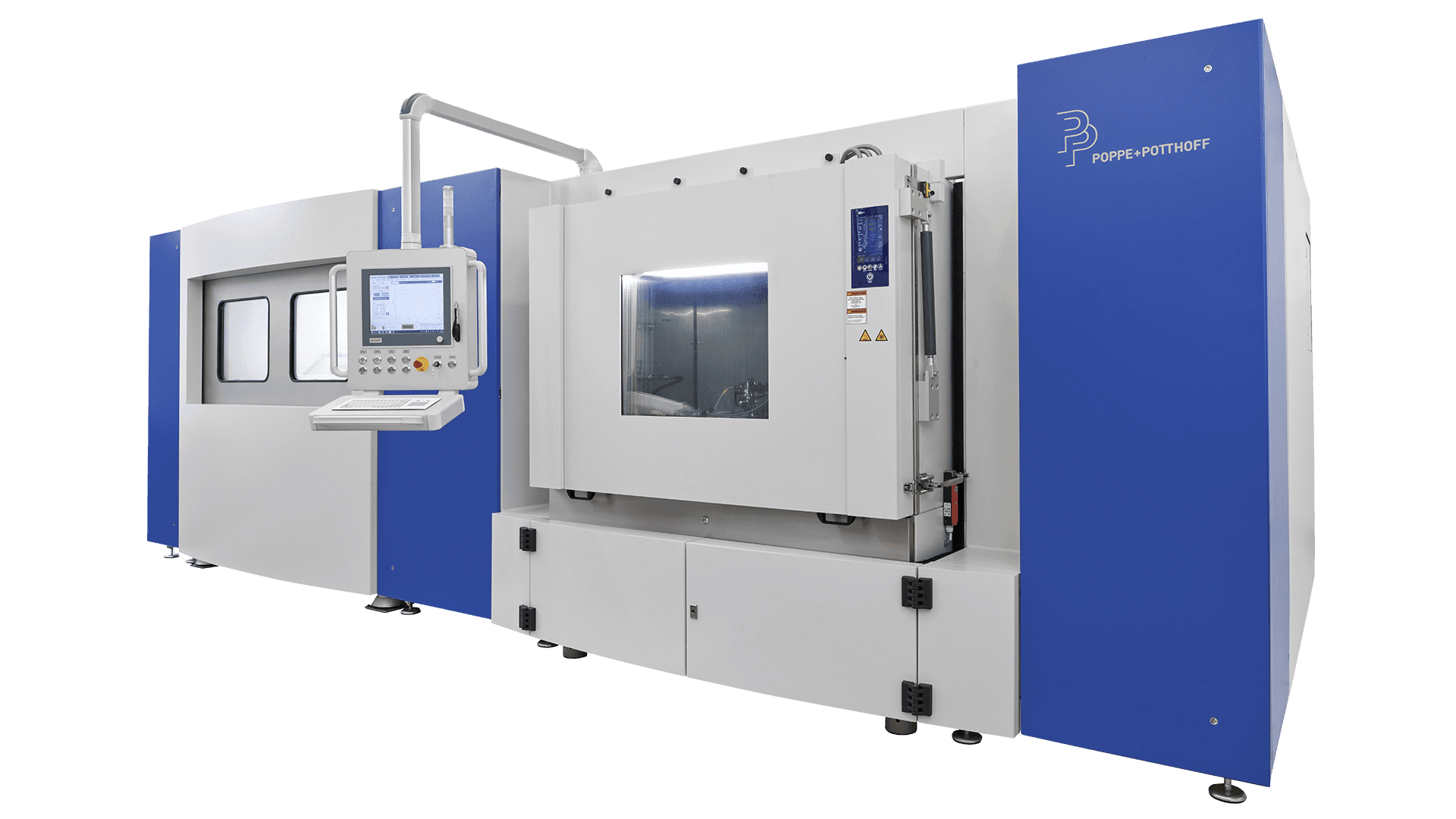

Safe and easy to use

Poppe + Potthoff Maschinenbau test systems are easy to operate and extremely safe. The test chamber consists of welded stainless steel and a high-strength polycarbonate safety window. Any test sequences created on the PC can simply be called up manually via coded recipe management or by a handheld scanner. The integrated LabView software from National Instruments enables efficient data acquisition and visualization. Test procedures and data are automatically stored on the system and can be exported to the network for evaluation. The open software structure makes it possible to integrate additional sensors and data during testing. Poppe + Potthoff Group can provide numerous testing services, remote maintenance and on-site technicians, if necessary.

Temperature ambient: -40°C to +160°C with rate of change 1,5 K/min

Temperature fluid: -40°C to +135°C

Test chamber: with Ex protection for pressure test with coolant (ATEX)

Size of test chamber: 1,500 x 900 x 900 mm (W x H x D)

Flow rate coolant: 0,5 l/min up to 30 l/min adjustable

Test pressure: dynamic up to 1,200 bar with sinus- and trapezoidal curve

Frequency: up to 2 Hz (further frequencies upon request)

Pressure drop test: up to 1,000 mbar

Static pressure test: up to 20 bar with compressed air and adjustable pressure increase

Leak rate test: 0,5 cm3/min

Vacuum testing: Pressure variation between atmosphere and 18 mbar abs.

Leakteststand <1050 bar with Gas (Helium)

Performance:

R & D Pressure pulsation & burst test stand for

H2 components up to 2,000 bar

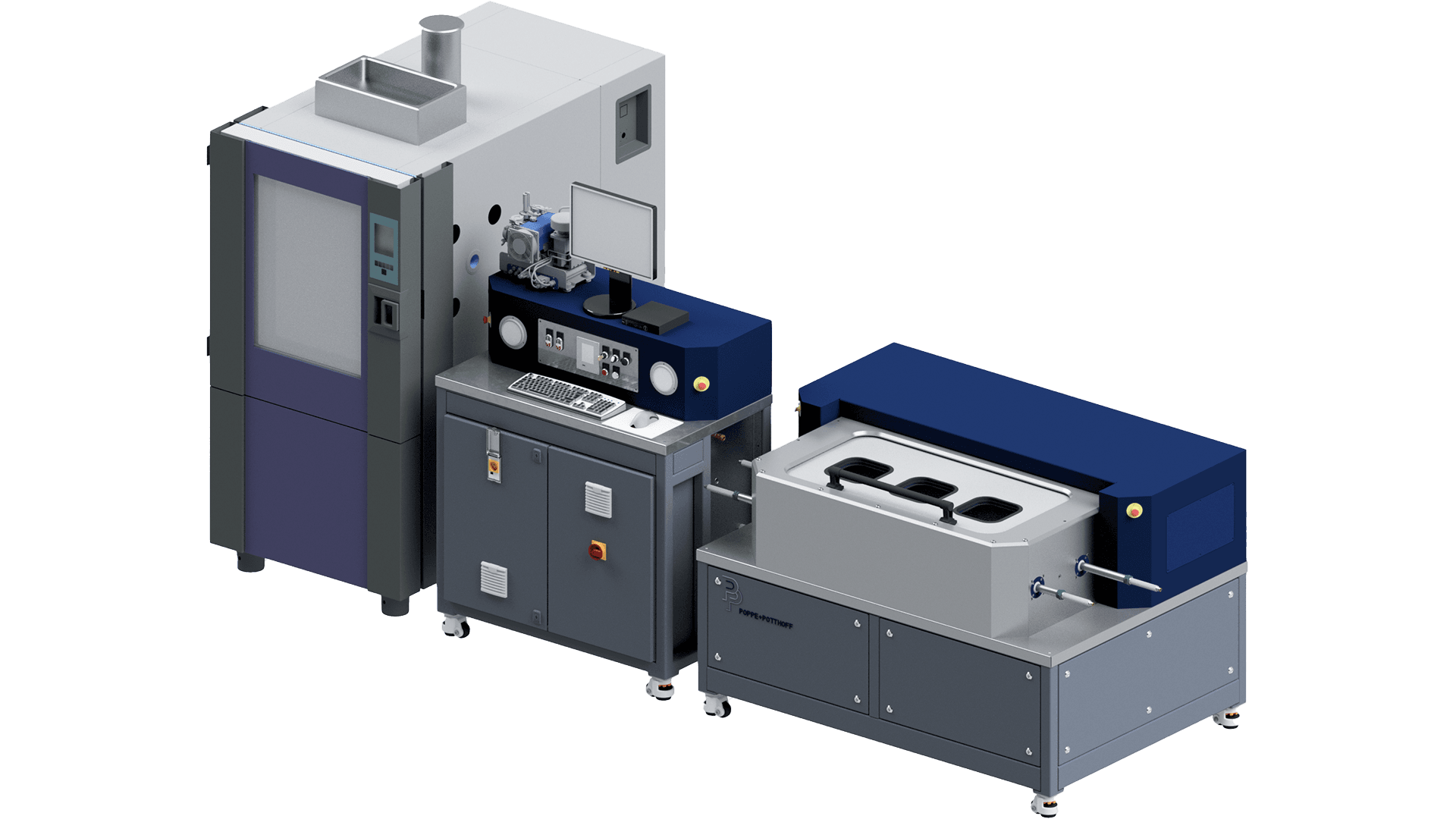

The system is a self-sufficient unit and is made of a solid welded frame, contains media preparation, a hydraulic unit and electrical engineering. The pressure test bench has a secure test chamber for burst pressure and hydrostatic pressure tests and, optionally, a climatic chamber for pressure tests with environmental simulation. Depending on the option selected, pressure change tests up to 2,000 bar and 10 Hz can be generated. With the test circuit for hydrostatic and burst pressure tests, pressure ramps up to 3,000 bar can be generated. It is operated on a support arm PC.

Pressure Tests by EG79 / EU406 – Abschnitt 4.2