Pressure Test Stands For

Marine & Shipbuilding-Components

At Poppe + Potthoff we serve many industries and marine and shipbuilding applications are frequently tested on our rigs. Ship engines are assembled with many components. Many of them are exposed to high pressures and thus require substantial pressure testing. Consequentially, engine parts for fuel injection such as diesel or ING, and recently also hydrogen, are tested with pressure cycle rigs and strength tests. In addition, some rails or injection nozzles are exposed to autofrettage processes. Further, ship engine cooling systems, pumps and valves are exposed to pressure and frequently tested with Poppe + Potthoff pressure test rigs.

Poppe + Potthoff offers a wide range of pressure test rigs that are utilized in the shipbuilding industry. Find a fitting rig and contact us to discuss your unique project.

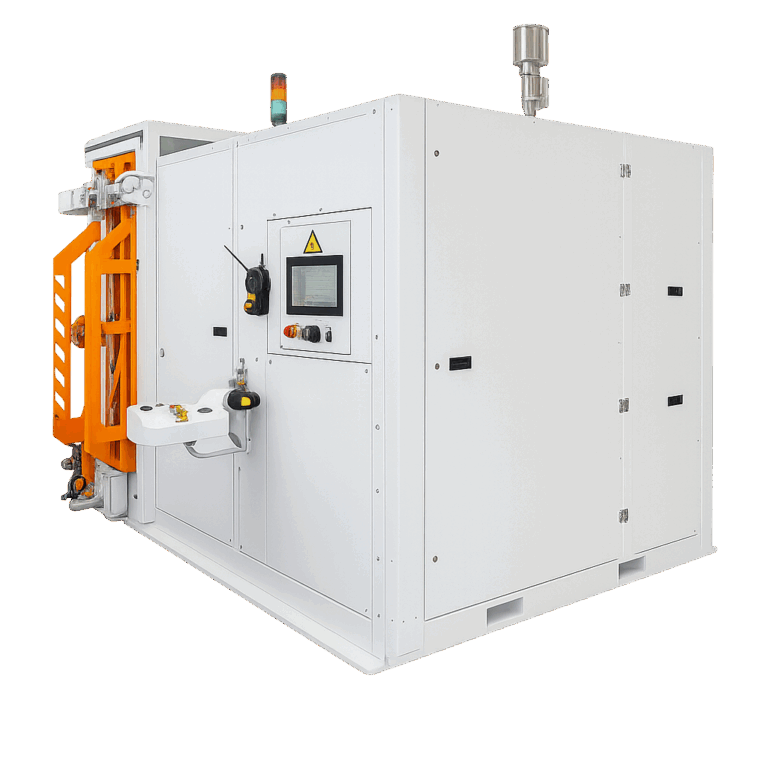

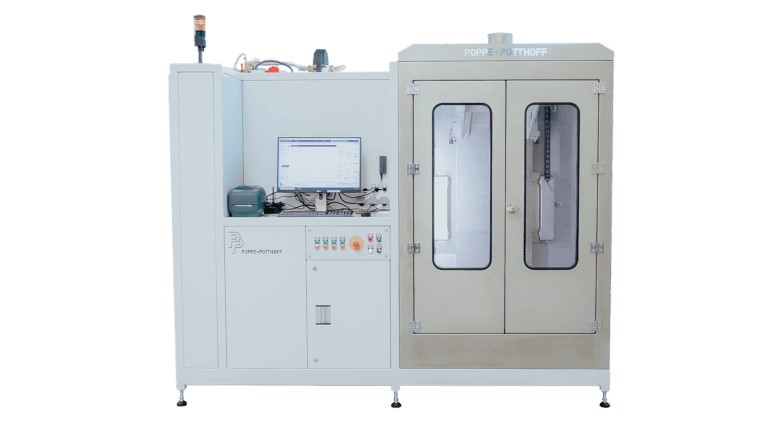

6000 bar impulse test stand

Developed in cooperation with Maximator, this 6000 bar pressure impulse test stand combines robust high-pressure technology with advanced control and hydraulic systems. Equipped with a hydraulic pressure intensifier, a Bosch Rexroth hydraulic unit, and a Siemens PLC, it ensures precise, repeatable pressure cycling for demanding endurance and fatigue tests. Contact us to learn more.

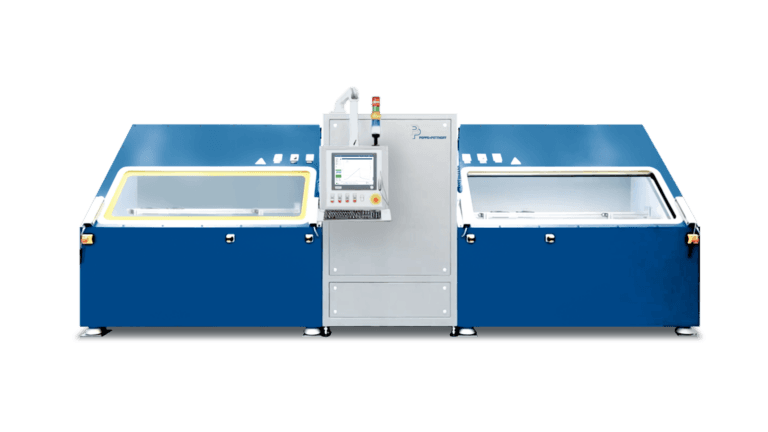

Autofrettage- & Pressure Proof for COPVs

Our test benches are specifically developed for Composite Overwrapped Pressure Vessels (COPVs) and other high-pressure containers. Using filtered water as the test medium, they enable precise autofrettage and pressure hold procedures to validate strength, increase durability, and extend vessel life. With pressure ranges up to 1050 bar, the systems are adaptable to different COPV sizes and volumes. A robust steel safety chamber ensures maximum protection in case of rupture, while the automated pre-filling process minimizes air entrapment for reproducible and safe testing. The integrated tilting device simplifies the handling of large and heavy vessels. Siemens PLC control, combined with an intuitive HMI, provides recipe management, complete data traceability, and reliable acquisition of key parameters, including pressure curves, hold times, expansion…

Test Rig for Acoustic Emission Testing of High-Pressure Composite Tubes

Our test stand solution for Acoustic Emission Analysis (SEA) enables the early and non-destructive detection of material defects in high-pressure composite fiber tubes. With automated pressure testing up to 1,000 bar, flexible test mandrels, and integrated safety monitoring, the system offers maximum process reliability and efficiency. During the test cycle, the measurement technology captures all relevant acoustic events, ensuring complete and traceable quality documentation. In this way, you safeguard the integrity of your products and meet the highest testing standards.

Liquid Cooling Burst- and Pressure Cycle Test Rig

Poppe + Potthoff Maschinenbau leads in burst and pressure pulsation testing for liquid cooling components like coolant distribution racks, manifolds, and CPU/GPU cold plates. Our rigorous testing ensures these components can withstand extreme pressure fluctuations, with burst pressures up to 70 bar (1100 psi) and pressure cycle testing at up to 20 bar (290 psi) using PG25 coolant. We utilize both wave and square pressure curves at frequencies up to 2 Hz, providing a comprehensive simulation of operational conditions. Additionally, our testing of passive cold plates, which rely on external Coolant Distribution Units (CDUs), further guarantees system reliability by mitigating internal pump failure risks.

Burst- and Pressure Pulsation Testing Cold Plates

Poppe + Potthoff Maschinenbau’s test rigs provide essential burst and pressure pulsation testing for liquid-cooled cold plates in server technology, mirroring practices from the automotive industry. Designed to verify component durability and seal integrity under fluctuating cooling circuit conditions, our rigs handle up to 35 bar (500 psi) in burst pressure and 12 bar in pressure cycle testing with PG25, at frequencies up to 2 Hz. These tests are vital for ensuring the reliability of cooling systems in CPUs, GPUs, and similar hardware. For more information, visit our product page.

Large Components | Burst- and Pressure Cycle Test Rig

The test stand has two large chambers in which individual burst pressure and pressure cycle tests can be executed. Our state-of-the-art P+P flex pressure intensifier covers large components, such as accumulators, and generates pressure load changes of up to 800 bar with a frequency of up to 10 Hz.

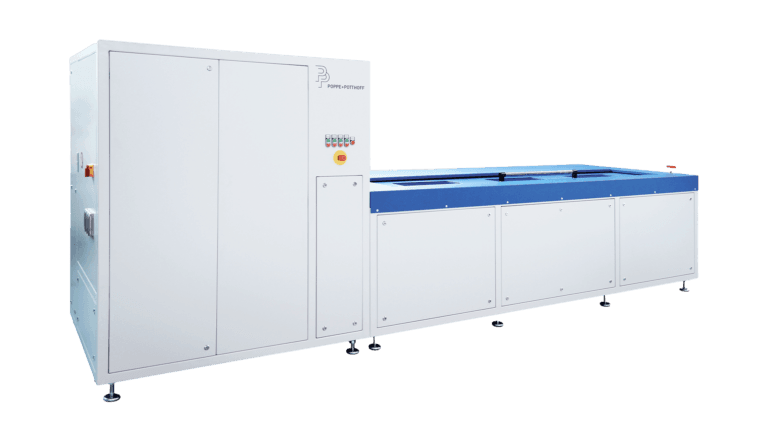

Hose Test Bench with Laser Measurement

When hoses are subjected to pressure, they often change from their original form and dimension. The test stand has an integrated automatic laser and length measurement system and can measure torsion easily. In addition, a quick connector system enables the hoses to be replaced rapidly.

Contact Us

Our experienced technical sales team will help you with the implementation of your project and will find a solution tailored to your specifications and your requirements. We are represented internationally and can support you and your company worldwide. Our team has completed hundreds of projects many of which involved supporting test facilities with identical equipment. P+P Maschinenbau is your internationally trusted partner.